PSI vs GPM: Surface-First Cleaning Guide

If you're struggling to understand PSI vs GPM when choosing power washer pressures, you're not alone. Homeowners and small operators routinely damage surfaces because they prioritize machine specifications over material needs. The truth is, effective pressure washing isn't about maxing out your machine (it's about finding the precise intersection where water flow rate meets surface tolerance). This guide cuts through the marketing hype with a surface-first approach that prevents damage while delivering professional results.

Why PSI vs GPM Confusion Causes Damage

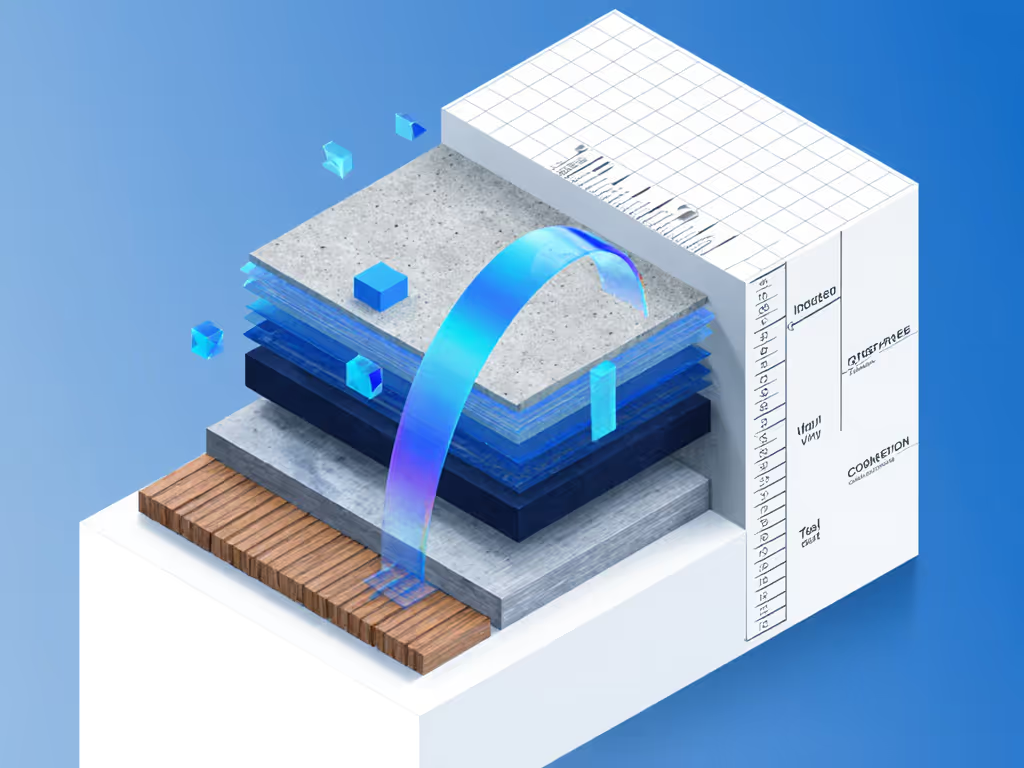

Most pressure washer comparisons focus exclusively on PSI (pounds per square inch) as the ultimate measure of cleaning power. But PSI alone tells only half the story. While PSI represents the pressure measurement of water force, GPM (gallons per minute) determines your water flow rate (the volume moving through the system). Neither number matters if you don't understand how they interact with your specific surface.

Consider this: A machine with 3000 PSI and 2.0 GPM delivers the same theoretical cleaning power (6,000 cleaning units) as a 2000 PSI/3.0 GPM unit. But which one actually works better? The answer depends entirely on your surface type. Hard concrete might need that higher PSI punch, while cedar decking requires the gentler flow of higher GPM at lower PSI to avoid raised grain.

Start with the surface; pressure is the last knob.

The Cedar Steps Lesson: When PSI Exceeds Surface Tolerance

I once worked with a homeowner whose cedar steps developed persistent fuzzing after pressure washing. Initial tests showed 1800 PSI with a narrow nozzle was literally tearing apart the wood fibers. By dropping to 1100 PSI, switching to a 40° nozzle for wider coverage, increasing dwell time with an oxygen cleaner, and following the grain direction, we eliminated the fuzzing while maintaining even color. The oxidation risk disappeared along with the drying lines. This case exemplifies why finish-safe thresholds must be determined through surface testing, not machine specs.

Step-by-Step: Finding Your Surface's Safe Threshold

Follow this decision tree to establish your optimal pressure washing setup without trial-and-error damage:

Step 1: Identify Your Surface Type

Different materials have dramatically different pressure tolerances: For material-by-material techniques and safe settings, see our exterior surfaces pressure washing guide.

- Soft woods (cedar, pine): 500-1,200 PSI at 12-18" standoff

- Hardwoods (mahogany, ipe): 1,200-1,800 PSI at 10-15" standoff

- Composite decking: 1,500-2,000 PSI at 12-24" standoff

- Concrete/pavers: 2,500-3,500 PSI at 6-12" standoff

- Vinyl/composite siding: 1,000-1,500 PSI at 12-18" standoff

- Brick/masonry: 1,500-2,500 PSI at 12-24" standoff

Step 2: Calculate Required Cleaning Units

Your cleaning units calculation (PSI × GPM) determines overall cleaning capacity, but only when properly matched to surface needs. For most residential applications:

- Delicate surfaces: 800-1,800 cleaning units

- Standard residential: 1,500-2,500 cleaning units

- Heavy-duty: 2,500+ cleaning units

Rather than chasing maximum numbers, focus on the minimum effective cleaning units for your surface. Higher isn't better, and it's often destructive.

Step 3: Determine Your Nozzle Strategy

Nozzle angle and standoff distance affect pressure more dramatically than most realize. A 0° nozzle delivers 100% of machine PSI, while a 40° nozzle reduces effective pressure by approximately 60%. This chart shows the relationship:

| Nozzle Angle | Effective PSI | Ideal Standoff Distance |

|---|---|---|

| 0° | 100% | 24-36" (safety only) |

| 15° | 75% | 12-18" |

| 25° | 50% | 10-15" |

| 40° | 40% | 8-12" |

| 65° | 25% | 6-10" |

Step 4: Optimize Dwell Time and Technique

Dwell time often gets overlooked in PSI vs GPM discussions, yet it's frequently the difference between success and damage. For oxidized surfaces or mildew:

- Apply detergent at low pressure (500-700 PSI)

- Allow 5-10 minutes of dwell time for chemical action

- Begin washing at maximum safe standoff distance

- Gradually decrease standoff while monitoring surface reaction

- Maintain consistent stroke speed (1-2 feet per second)

- Respect the grain when washing wood surfaces

Surface Coverage: The Hidden Efficiency Factor

Your effective surface coverage depends more on proper technique than raw machine power. A common mistake is using too narrow a spray pattern, forcing repetitive passes that waste time and water. Here's the efficiency formula:

Square Feet per Minute = (Nozzle Pattern Width in feet) × (Stroke Speed in feet per second) × 60

For example, a 40° nozzle creates approximately a 12" wide pattern at 12" standoff. At a proper 1.5 feet per second stroke speed, you'd cover 90 square feet per minute. Pushing harder by decreasing standoff might increase coverage slightly, but it dramatically increases oxidation risk and surface damage probability.

The Finish-Safe Decision Matrix

- Wood surfaces: Prioritize higher GPM at lower PSI (1,000-1,500 PSI range)

- Use 40° nozzle minimum

- Maintain 12"+ standoff

- Dwell time 5+ minutes with oxygen cleaner

- Follow grain direction exclusively

- Composite materials: Moderate PSI with precise standoff control (1,500-2,000 PSI)

- 25°-40° nozzle

- 10-15" standoff

- Watch for whitening (sign of excessive pressure)

- Concrete/pavers: Higher PSI acceptable but watch mortar joints (2,500-3,000 PSI)

- 15°-25° nozzle

- 6-12" standoff

- Move constantly to prevent etching

- Vinyl/composite siding: Low PSI critical (1,000-1,500 PSI)

- 40° nozzle minimum

- 12-18" standoff

- Work bottom to top to prevent water intrusion

Taking Action: Your Next Surface Test

Before your next pressure washing project, conduct this simple test on an inconspicuous area:

- Start at manufacturer-recommended PSI settings

- Increase pressure incrementally by 200 PSI

- Note when surface fibers begin to lift or texture changes

- Back off 20% from that threshold

- Document your safe PSI, standoff distance, and dwell time

This tiny investment of time prevents costly damage and delivers consistent results across all your surfaces. Remember that the most powerful pressure washer isn't the one with the highest numbers; it's the one that respects your surfaces' unique needs. When you understand the relationship between PSI vs GPM through a surface-first lens, you'll achieve professional results without the risk of rework or damage.

Start with the surface; pressure is the last knob.

Actionable next step: Grab your pressure washer, a notebook, and test a small hidden area of your deck or siding tomorrow morning. Document the PSI, nozzle angle, and standoff where you first notice surface disturbance, then back off to find your finish-safe threshold. This five-minute test will save you hours of rework and potentially thousands in surface repair costs.