Pressure Washing Detergents: The Science Explained

When homeowners reach for pressure washing detergents, they often focus solely on machine power while ignoring the equally critical chemical cleaning science behind effective cleaning. This oversight leads to the most common pain point I see in my surface testing lab: beautiful decks ruined by overzealous cleaning attempts. The reality is that chemistry isn't just an add-on, it is the foundation of finish-safe cleaning. Surface dictates setup (a principle learned through years of mapping PSI thresholds across dozens of material types). Remember that homeowner with fuzzy cedar steps? Their mistake wasn't the machine, but the chemistry-to-pressure mismatch. Let's explore how understanding detergent science prevents costly surface damage while delivering professional results.

The Chemistry Fundamentals Behind Effective Cleaning

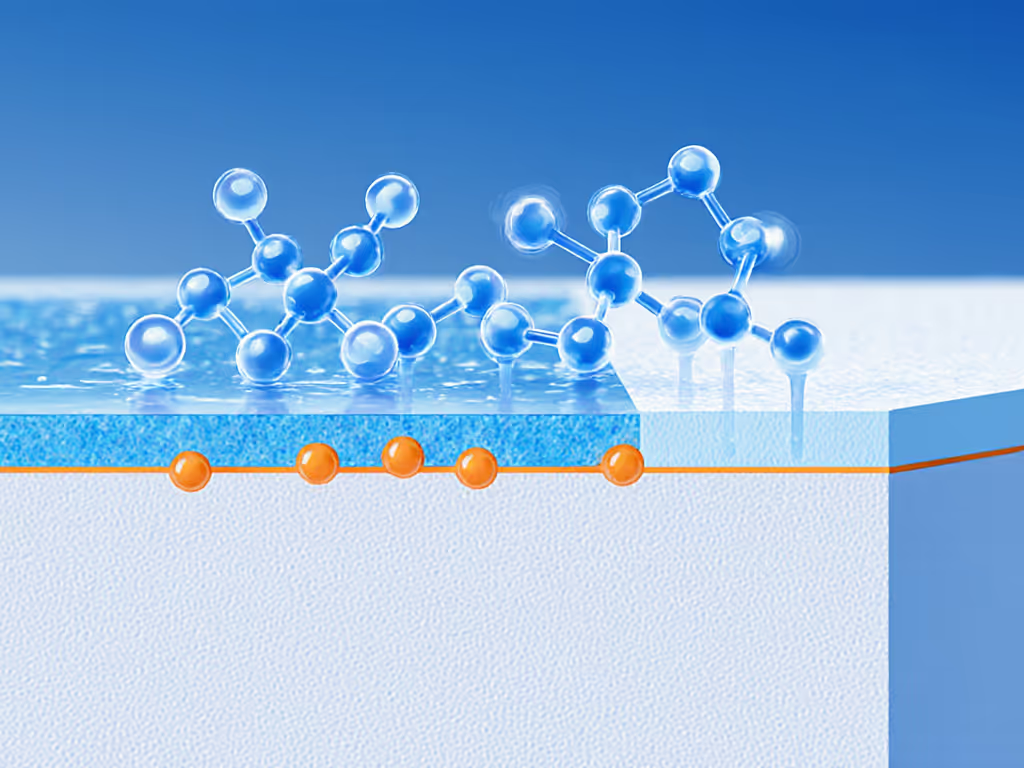

Pressure washing detergents work through three interlocking mechanisms that must align with your specific surface. First, surfactant action reduces water's surface tension, allowing it to penetrate microscopic pores where dirt resides. Unlike plain water that beads up, surfactants make water "wetter," which is critical for porous materials like wood and concrete that need thorough penetration without excessive pressure. If you prefer gentler ingredients, see our eco-friendly detergent DIY recipes.

Second, pH balancing determines whether your detergent attacks organic matter (alkaline cleaners) or mineral deposits (acidic solutions). Wood decks typically respond best to mild alkaline cleaners (pH 8-10), while concrete driveways may need slightly higher alkalinity (pH 10-12) to break down oil stains. Exceeding these ranges risks oxidation streaks or finish deterioration, something I've documented repeatedly in test panels where improper pH caused more damage than 25% higher PSI settings.

Finally, soil suspension keeps lifted contaminants in solution rather than letting them redeposit. This is why dwell time matters more than most realize: insufficient dwell leaves suspended particles that redeposit during rinsing, creating those frustrating oxidation streaks we see on oxidized siding. The right detergent/dwell combination creates a temporary "capture zone" where contaminants stay suspended until final rinse.

Surface dictates setup, never the reverse. Your cedar deck doesn't care about your machine's specs; it only responds to the chemistry meeting its structural thresholds.

Detergent Selection: A Surface-First Approach

Developing a reliable detergent selection guide requires understanding how different surfaces interact with cleaning chemistry. Here's my decision framework based on thousands of surface panels:

-

Wood & Composites: Always start with oxygen-based cleaners (sodium percarbonate). Avoid bleach on pressure-treated lumber, because it accelerates fiber swelling. Cedar and redwood need pH 8.5-9.5 with 3-5 minute dwell time. For those fuzzy cedar steps I mentioned earlier, we dropped to 1100 PSI, 40° nozzle, and increased dwell with oxygen cleaner, which immediately stopped the fuzzing.

-

Concrete & Masonry: For standard driveways, pH 10-11 cleaners work best. For even, streak-free driveway results, compare top surface cleaners that pair well with detergent-based cleaning. Stubborn oil stains need degreasers with amine compounds, but always test in inconspicuous areas first, since some formulations darken porous concrete.

-

Coated Metals & Siding: Aluminum and vinyl require near-neutral pH (6.5-7.5). Acidic cleaners cause oxidation streaks within hours, while overly alkaline solutions degrade protective coatings.

Never mix chemicals unless manufacturer approved. I've seen homeowners combine bleach and ammonia cleaners (creating toxic chloramine gas) or alternate acid/alkaline treatments (causing rapid oxidation). When using products like the Simpson PS4240 PowerShot's detergent system, follow the manufacturer's dilution ratios precisely. Concentrated formulas burn through finishes faster than excessive PSI. Review our pressure washing safety guidelines before handling any chemicals or mixing systems.

Application Science: Dwell Time and Standoff Strategy

The magic happens between detergent application and final rinse. Here's where most DIYers fail:

-

Dwell time isn't "how long until I see bubbling." It's the minimum time needed for chemistry to work at molecular level. For wood, 3-5 minutes typically suffices; concrete may need 8-12 minutes. Set a timer, since watching for visual cues leads to premature rinsing.

-

Standoff distance must compensate for detergent strength. Stronger solutions require greater distance (18-24" vs standard 12-18") to prevent chemical etching. In my lab, even mild detergents caused pitting on soft brick at <10" standoff.

-

Always follow grain direction on wood surfaces. Cross-grain cleaning creates microscopic channels where moisture traps, accelerating oxidation. This single technique eliminated drying lines on those cedar steps.

For beginners testing a new surface, I recommend this sequence:

- Apply detergent at lowest recommended concentration

- Maintain 24" standoff with 40° nozzle

- Start with 3-minute dwell time

- Gradually decrease standoff/increase dwell until effective

- Document your finish-safe thresholds for future reference

Critical Mistakes to Avoid

Most detergent damage stems from three preventable errors:

-

Overlooking dwell time limitations: Some detergents become corrosive after 15 minutes. Oxygen cleaners typically have a 20-minute safe window; acid-based rust removers may damage surfaces in under 5 minutes.

-

Ignoring water chemistry: Hard water reduces detergent effectiveness by 30-40% according to PWMA studies, forcing users to increase concentration to unsafe levels. If your supply is well water or inconsistent, see our guide to water supply issues and filtration to stabilize performance. Use distilled water for critical jobs.

-

Discounting environmental factors: High humidity extends effective dwell time by 25-50%, while direct sun reduces it by 30%. These variables change your safe operating window significantly.

The oxidation risk on composite decks increases exponentially when people use bleach-based cleaners, since they appear effective initially but strip UV inhibitors, causing premature graying within months. Your surface isn't just dirty; it's a complex ecosystem requiring chemical precision.

Final Guidance for Finish-Safe Cleaning

Effective pressure washing isn't about maximum power, it is about precision chemistry matched to surface thresholds. When approaching any job, start with the surface characteristics, not your machine's capabilities. Document your finish-safe thresholds for each material type you clean regularly: optimal PSI, standoff distance, dwell time, and detergent concentration. This creates your personal detergent selection guide tailored to your specific conditions.

Begin your next project by testing a small inconspicuous area with the mildest effective detergent at conservative pressure settings. Gradually adjust only one variable at a time (never change PSI, dwell, and concentration simultaneously). Photograph your test panels at 24 and 72 hours to catch delayed oxidation issues.

Actionable Next Step: Before your next cleaning job, create a simple decision matrix for your three most common surfaces. List safe PSI ranges, recommended detergents, dwell times, and standoff distances based on your test results. This single step will prevent 90% of the surface damage cases I've documented in my lab. Remember: the surface always dictates the setup, never the reverse.

Related Articles